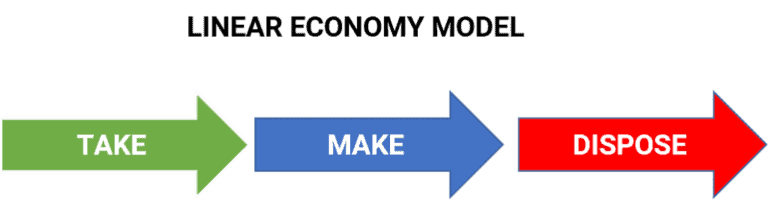

For a long time, our world followed the linear economy model. This model follows the “take, make and dispose” steps:-

1. Take: Raw materials are procured to manufacture a product

2. Make: The product is manufactured and used

3. Dispose: Once the product is used, it is thrown away. This is because the product is not recyclable or designed for reuse. The product is treated as waste.

The traditional linear economy model has led to accumulation of excess waste over the years. Due to mass production, waste generation increased dramatically and has led to widespread pollution. Some waste such as plastic waste could take several years to decompose. This has put an unprecedented strain on our Environment and planet. By 2050, it is projected that we will be consuming materials and generating waste as if we had three planet Earths instead of one.[i]

The linear economy model is no longer an option for our finite planet. Our planet requires a more ecological model in which waste is minimized and products are recycled and reused for as long as possible. This is where the circular economy comes into picture.

What is Circular Economy?

What is Circular Economy?

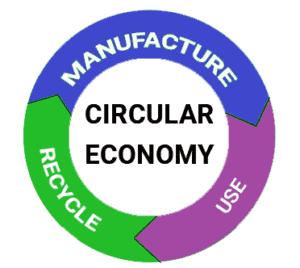

Circular economy is an economic system in which the value of products and their raw materials are preserved for as long as possible.

Instead of the “take, make and dispose” steps, this model follows the “make, use and recycle” steps. In this way, the model aims to reduce waste and protect our Environment.

It also encourages sustainable economic growth. As per a recent study, it is estimated that applying circular economy initiatives in the EU economy can lead to an additional increase in the EU GDP by 0.5% by 2030 and creation of 700,000 new jobs.[ii]

Recognizing the potential environmental and economic advantages of circular economy in the EU, the European Commission has formulated the new Circular Economy Action Plan (CEAP) in 2020.[iii] This action plan outlines key initiatives that shall be considered along the entire product life cycle to ensure preservation of products’ values for as long as possible and waste minimization.

The CEAP recognizes that one of the key value chains in which circular economy can be effectively implemented is in the packaging industry.

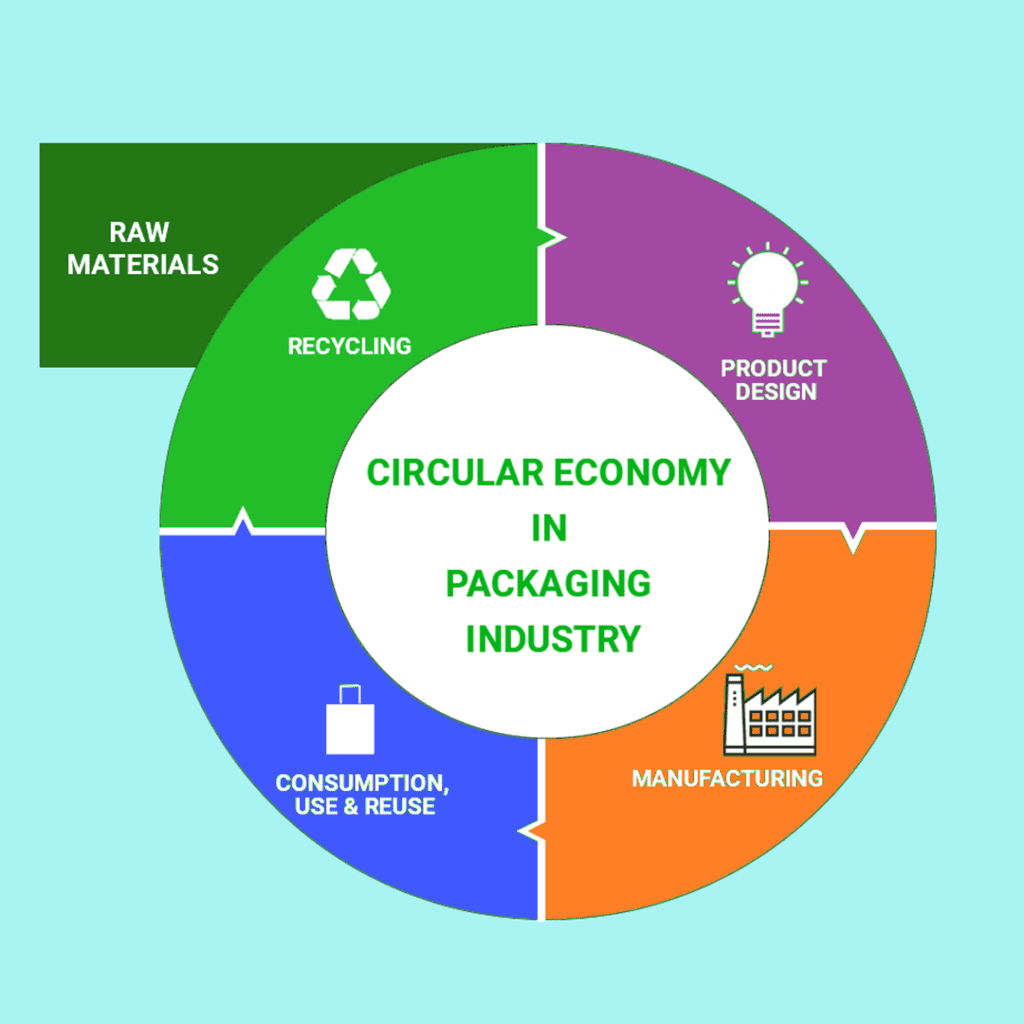

The circular economy cycle in the packaging manufacturing industry is as follows:

In the product design phase, it is essential that the packaging is designed for reusability and high quality recycling. Moreover, it is important that the packaging is designed to contain less packaging materials to minimize waste. The manufacturing process should contribute to reduction in carbon and environmental footprints.

As a manufacturer of virgin sack kraft paper and paper bags, we contribute to the circular economy cycle of the packaging value chain in the EU.

By design, our virgin sack kraft paper and paper bags are fully recyclable, reusable, biodegradable and renewable. We manufacture our paper bags with our own manufactured sack kraft paper only, thereby extending the value of our paper to our paper bags and simplifying packaging materials used. We use 80% renewable energy in our manufacturing to reduce environmental footprint. Due to our paper bags consisting of long virgin fibers, our bags are strong and can be reused several times. Our bags can then be recycled and repulped, which allows for manufacturing of other paper based products in the European packaging value chain.

Even after you reuse our paper and paper bags, you can be assured that they take a new life in the form of other paper products after being recycled. Their value continues to be retained for as long as possible.

References:

[i] https://www.un.org/sustainabledevelopment/sustainable-consumption-production/

[ii] Impacts of circular economy policies on the labour market. (2018). Cambridge Econometrics, Trinomics, and ICF.

[iii] Circular Economy Action Plan. (2020). European Commission.